Producing a quality railway mug – how it’s done . . .

Producing a mug to the quality and standard we aspire to has taken a great deal of time and effort on the part of many people. Here is an overview of what it takes to make a mug to this standard.

Stage 1 : Painting the locomotive

A locomotive portrait is painted my renowned transport artist Jonathan Clay which can take weeks to complete. Jonathan’s paintings were chosen for their quality and accuracy – they are typically painted at a size of 20”x 16” or 14” x 11” using gouache paint. The selected painting is scanned and reduced to produce a digital image at the right size to feature on one of our bone china mugs.

A locomotive portrait is painted my renowned transport artist Jonathan Clay which can take weeks to complete. Jonathan’s paintings were chosen for their quality and accuracy – they are typically painted at a size of 20”x 16” or 14” x 11” using gouache paint. The selected painting is scanned and reduced to produce a digital image at the right size to feature on one of our bone china mugs.

Stage 2 : Turning the picture into a mug motif

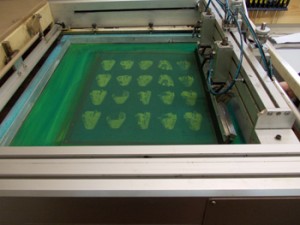

In order to get the best possible quality image, a silk screen ceramic printing process is used by Ceramicraft in Stoke on Trent. This involves separating the digital image from stage 1 above into 4 colours – Yellow, Magenta (light red), Cyan (light blue) and Black. For each colour a silk screen stencil is made.

Each stencil is used in the screen printing machine to apply one particular colour to the image.  The image has to pass through this process 4 times with one of the 4 colours being applied on each pass – it is therefore critical that the colour stencils are aligned precisely at each pass otherwise the final image will look blurred. The humidity and temperature are carefully monitored to ensure this process happens perfectly as these things can make the paper or image contract or expand.

The image has to pass through this process 4 times with one of the 4 colours being applied on each pass – it is therefore critical that the colour stencils are aligned precisely at each pass otherwise the final image will look blurred. The humidity and temperature are carefully monitored to ensure this process happens perfectly as these things can make the paper or image contract or expand.

The final image is sealed with a transparent yellow covering varnish which holds the image in place whilst being applied to the mug but which burns off during the firing process.

The sheets of motifs are then left to dry for at least 8 hours.

The paints used in the process are special ceramic colours which can withstand the 820ºc firing process and normal day to day mug use such as sunshine, hot tea and dish washers – which ensures the image on the mug will remain vibrant and not fade.

The paints used in the process are special ceramic colours which can withstand the 820ºc firing process and normal day to day mug use such as sunshine, hot tea and dish washers – which ensures the image on the mug will remain vibrant and not fade.

As the correct livery of the locomotive is vital to producing a quality railway mug, test samples are produced, applied to mugs and fired many times so that the colours can be tweaked until the right shades are achieved.

Stage 3 : Applying the picture to the mug

The completed sheets of motifs are sent to our mug manufacturer in Scotland. Here they are cut into individual mug pictures – each picture is then placed in water until soaked through which enables the picture to slide off the backing paper and onto the large bone china mug.

The completed sheets of motifs are sent to our mug manufacturer in Scotland. Here they are cut into individual mug pictures – each picture is then placed in water until soaked through which enables the picture to slide off the backing paper and onto the large bone china mug.

All this is done by hand to ensure the picture is at the right place on the mug both front and back. The mugs are then fired for 10 hours at a temperature of 820° centigrade (very very hot!). This temperature seals the picture within the glaze of the mug and ensures it’s long lasting protection.

Each mug is finally inspected to ensure the picture production and firing have all worked together in producing a quality railway mug !